The fashion industry has always been driven by creativity, innovation, and technology. From the invention of the sewing machine to the rise of computer-aided design (CAD), fashion continuously evolves to reflect modern technology and cultural trends. Today, one of the most groundbreaking advancements transforming the industry is 3D printing — a technology that is redefining how garments, accessories, and footwear are designed, produced, and customized. This innovation marks the dawn of a new era in fashion, where sustainability, personalization, and creative freedom take center stage.

What Is 3D Printing in Fashion?

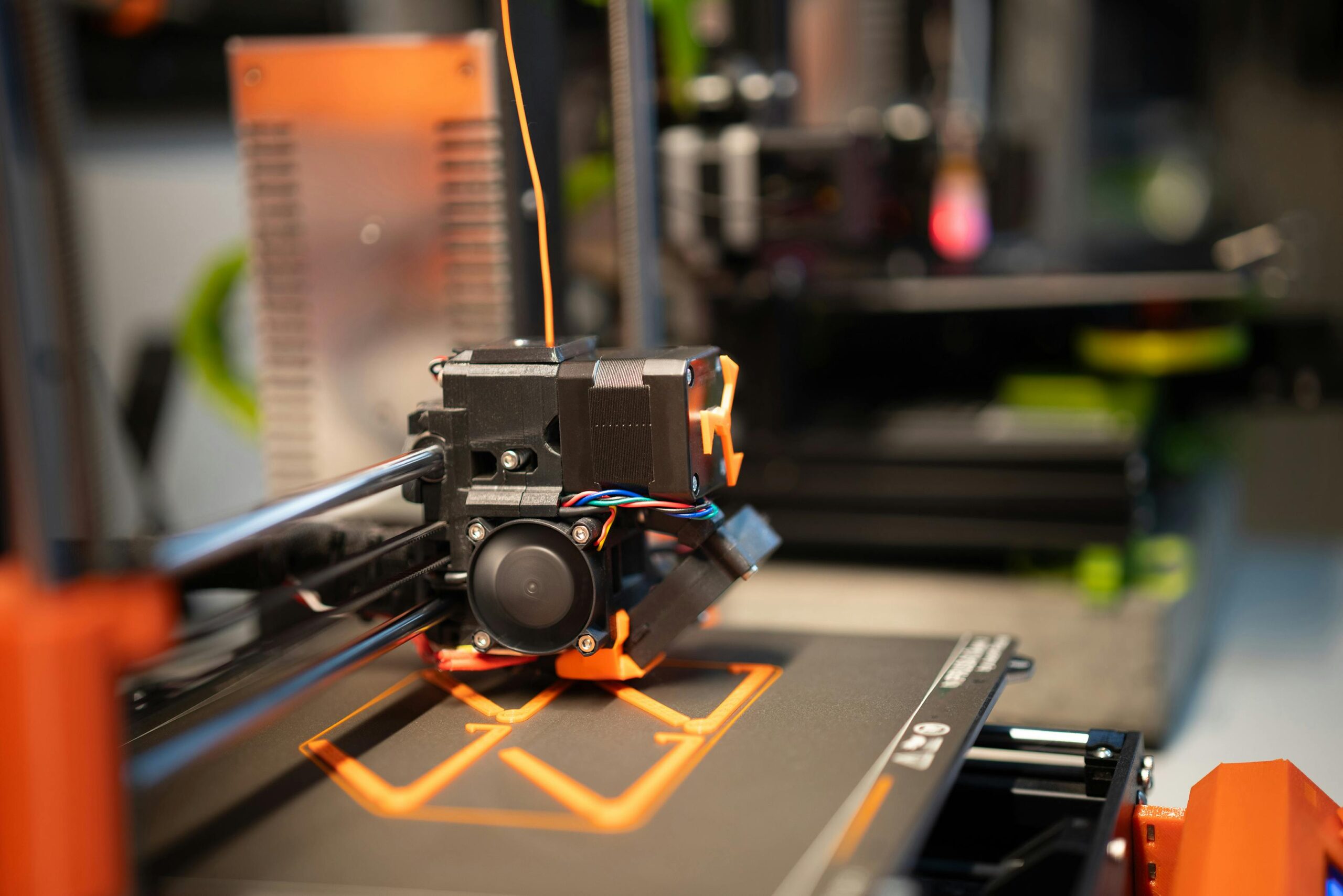

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by building them layer by layer from digital designs. Unlike traditional methods, which involve cutting, sewing, and assembling materials, 3D printing produces complete structures directly from a computer model. In fashion, designers use specialized printers and materials such as nylon, resin, thermoplastic polyurethane (TPU), and even biodegradable filaments to craft intricate and durable designs.

This technology allows for unprecedented levels of precision and creativity. Designers can create complex geometric patterns, organic forms, and textures that are impossible or too costly to produce using traditional techniques. From avant-garde runway pieces to wearable everyday clothing, 3D printing is gradually reshaping the boundaries of what fashion can be.

The Evolution of 3D Printing in Fashion

The concept of 3D printing in fashion began to gain attention in the early 2010s, when experimental designers started using it for haute couture. One of the pioneers was Iris van Herpen, a Dutch designer who showcased stunning 3D-printed dresses at Paris Fashion Week. Her collections demonstrated the potential of this technology as an artistic tool, combining engineering and aesthetics in a way never seen before.

As technology advanced, the fashion industry began to adopt 3D printing beyond high fashion. Major brands like Adidas, Nike, and Reebok started experimenting with 3D-printed sneakers, while luxury houses such as Chanel and Dior explored accessories and embellishments made with additive manufacturing. Today, 3D printing has moved from the design studio into the commercial sphere, making fashion more accessible, customizable, and sustainable.

Customization: Fashion Tailored for the Individual

One of the most exciting advantages of 3D printing is its ability to offer true customization. Traditional fashion production relies on standard sizes, which rarely fit every individual perfectly. However, with 3D printing, garments and accessories can be designed specifically for the wearer’s body measurements.

For instance, 3D body scanning technology can capture a person’s exact dimensions, and designers can use this data to create clothing that fits like a second skin. This level of personalization not only improves comfort and appearance but also enhances the overall shopping experience. Consumers can become co-designers, choosing materials, colors, patterns, and shapes that reflect their unique identity.

Graph 1: Growth in Custom Fashion Demand (2020–2025)

| Year | Market Size (in Billion USD) | Growth Rate (%) |

|---|---|---|

| 2020 | 0.8 | — |

| 2021 | 1.1 | 37.5 |

| 2022 | 1.5 | 36.3 |

| 2023 | 2.1 | 40.0 |

| 2024 | 2.9 | 38.1 |

| 2025 (Projected) | 3.9 | 34.4 |

This projected growth shows how consumers increasingly prefer customized, made-to-order fashion, a demand 3D printing can efficiently meet.

Sustainability: Reducing Waste and Environmental Impact

One of the major challenges facing the fashion industry today is environmental sustainability. Traditional manufacturing methods generate enormous waste — from fabric scraps to unsold inventory. According to reports, the fashion industry contributes up to 10% of global carbon emissions and produces 92 million tons of textile waste annually.

3D printing offers a promising solution to these issues. Because the process is additive rather than subtractive, it uses only the material needed to create an item, significantly reducing waste. Furthermore, many 3D printing materials are recyclable or biodegradable, minimizing environmental impact.

Brands are also exploring on-demand production models, where clothes and accessories are printed only after a customer places an order. This reduces overproduction — a major cause of waste in fast fashion — and leads to a more responsible, circular fashion economy.

Innovations in 3D Printing Materials

The success of 3D-printed fashion depends heavily on the materials used. Early 3D-printed garments were often stiff and uncomfortable, limiting their practicality. However, advancements in material science have introduced new, flexible, and breathable filaments that mimic the qualities of traditional fabrics.

Some notable innovations include:

-

TPU (Thermoplastic Polyurethane): Offers elasticity and durability, ideal for footwear and sportswear.

-

Nylon and Polyamide: Lightweight, flexible, and suitable for intricate designs.

-

Recycled Polymers: Made from post-consumer plastic waste, promoting sustainability.

-

Bio-based Materials: Derived from natural sources like algae or cornstarch, offering biodegradable alternatives.

Researchers are even developing smart materials that respond to environmental changes — such as temperature or movement — opening up new possibilities for interactive fashion.

3D Printing in Footwear and Accessories

3D printing has found particularly strong applications in the footwear industry. Brands like Adidas and Nike have used it to create custom midsoles and performance-enhancing components. Adidas’s Futurecraft 4D shoes, for instance, use a 3D-printed lattice structure that provides personalized cushioning based on the wearer’s movement patterns.

In accessories, designers are experimenting with 3D-printed jewelry, bags, and eyewear, blending style with innovation. For example, eyewear brands can now produce custom-fit glasses frames based on facial scans, ensuring perfect comfort and aesthetics for each customer.

The Role of 3D Printing in High Fashion and Couture

While 3D printing is making fashion more practical and sustainable, it has also become a powerful tool for artistic expression in haute couture. Designers like Iris van Herpen, Danit Peleg, and Julia Koerner have shown that 3D printing can transform fashion into wearable art.

These designers collaborate with engineers and architects to create garments that merge architecture, biology, and technology. The results are intricate, futuristic pieces that push the boundaries of what fabric and form can achieve. Such collaborations signal a shift in the creative process — where fashion design becomes an interdisciplinary art form.

3D Printing and the Future of Mass Production

One of the biggest potentials of 3D printing lies in redefining mass production. Traditionally, manufacturing involves multiple steps — cutting, sewing, dyeing, and assembling — often spread across several countries. This process consumes time, energy, and resources.

3D printing simplifies production by enabling local manufacturing. A digital file can be sent anywhere in the world and printed locally, reducing shipping costs and carbon emissions. This decentralization allows smaller brands and independent designers to compete with global companies, democratizing the fashion landscape.

Moreover, 3D printing enables rapid prototyping, allowing designers to test ideas quickly without the need for expensive molds or materials. This accelerates innovation and shortens the design-to-market timeline.

Graph 2: Adoption of 3D Printing in the Fashion Industry

| Segment | Current Adoption (%) | Projected Adoption by 2030 (%) |

|---|---|---|

| Footwear | 35 | 70 |

| Apparel | 25 | 60 |

| Accessories | 20 | 55 |

| Jewelry | 40 | 75 |

| Prototyping | 50 | 85 |

This data highlights the rapid expansion of 3D printing applications across various fashion segments, driven by advancements in materials, affordability, and design capabilities.

Challenges and Limitations

Despite its promise, 3D printing in fashion still faces several challenges:

-

High Costs: While prices are decreasing, industrial-grade 3D printers and materials remain expensive for small-scale designers.

-

Production Speed: Printing complex designs can be time-consuming, limiting mass production scalability.

-

Comfort and Durability: Some 3D-printed materials still lack the softness and breathability of traditional fabrics.

-

Consumer Awareness: Many consumers are still unfamiliar with 3D-printed fashion, leading to slower market adoption.

However, as technology evolves, these challenges are gradually being addressed through material innovation, automation, and education.

Education and Skill Development

As 3D printing becomes more integrated into fashion, educational institutions are adapting their curricula to prepare the next generation of designers. Universities such as Parsons School of Design and London College of Fashion now offer specialized courses that combine fashion design, 3D modeling, and digital fabrication.

These programs encourage students to experiment with new technologies, fostering a mindset of innovation and sustainability. The fusion of art and engineering is becoming a core aspect of modern fashion education.

Consumer Experience and Digital Fashion

The rise of digital fashion — where clothing exists only in virtual spaces — has also benefited from 3D printing technology. Designers can use 3D modeling software to create outfits for avatars in the metaverse, video games, or virtual fashion shows.

Moreover, 3D printing allows physical counterparts of digital designs to be produced on demand, bridging the gap between virtual identity and real-world expression. This fusion of the digital and physical realms marks a significant step toward the future of phygital fashion (physical + digital).

The Future Outlook

The future of 3D printing in fashion looks incredibly promising. With ongoing improvements in material diversity, printer speed, and affordability, it’s likely that 3D-printed clothing will soon move from niche markets to mainstream retail.

In the coming decade, we can expect:

-

Fully personalized wardrobes created from body scans.

-

Home 3D printers allowing consumers to print their own fashion accessories.

-

Sustainable production cycles that minimize waste and promote circularity.

-

Collaborations between fashion brands and tech companies to push innovation further.

Ultimately, 3D printing represents more than just a technological advancement — it’s a philosophical shift toward a more inclusive, efficient, and environmentally conscious fashion industry.

Conclusion

3D printing is ushering in a new era of customization, sustainability, and innovation in fashion. By merging design creativity with digital precision, it enables garments and accessories that are both functional and expressive. From haute couture masterpieces to custom-fit sneakers, this technology empowers designers and consumers alike to reimagine the possibilities of personal style.

As 3D printing continues to evolve, it holds the potential to transform fashion from a mass-produced industry into a made-for-you experience, reshaping not only how we dress but also how we think about design, production, and consumption. The future of fashion is not just about what we wear — it’s about how we create it.

Leave a Reply